About Us

Here at Midwest Access, we believe in human power rather to diesel power.

About us

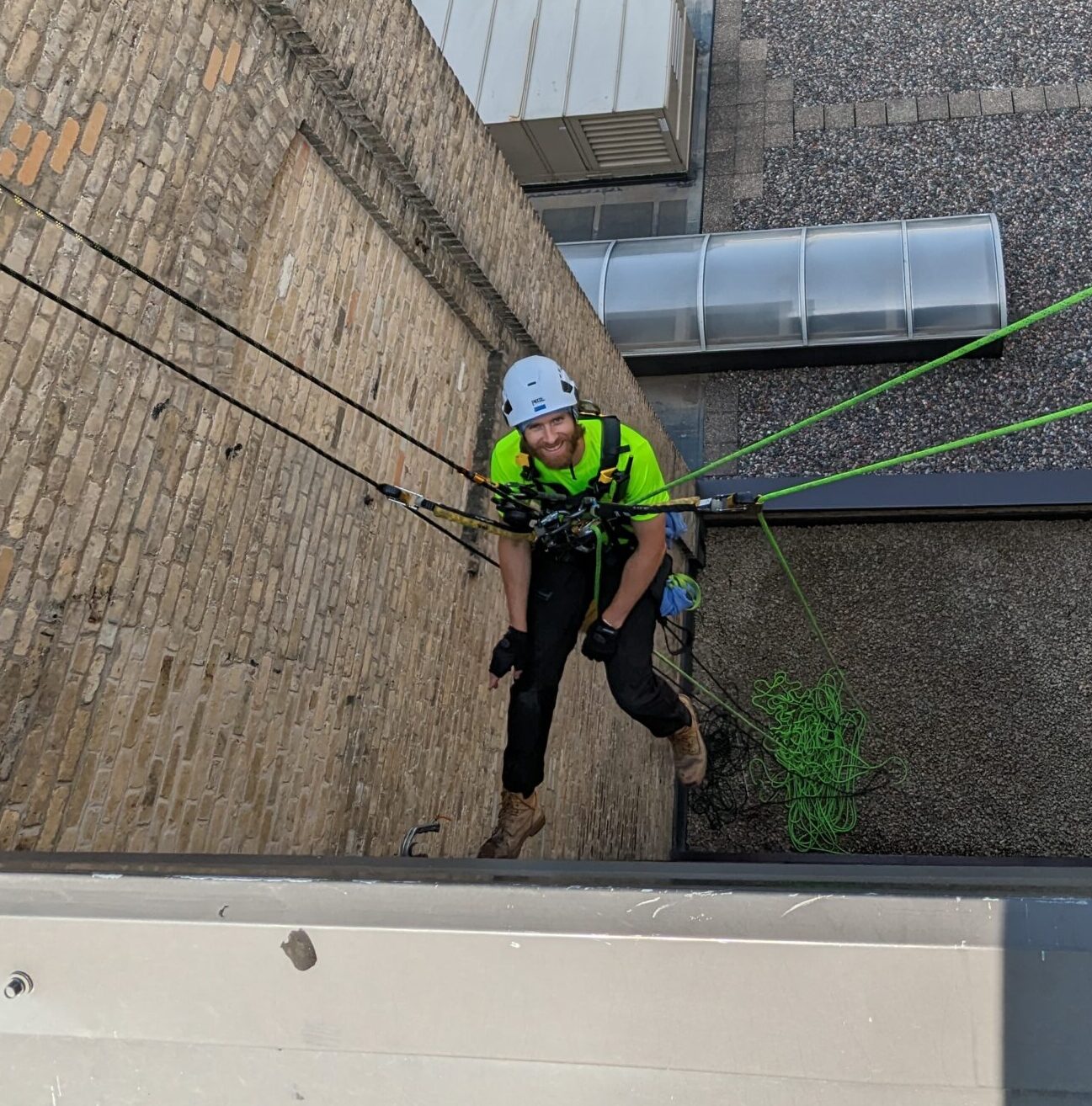

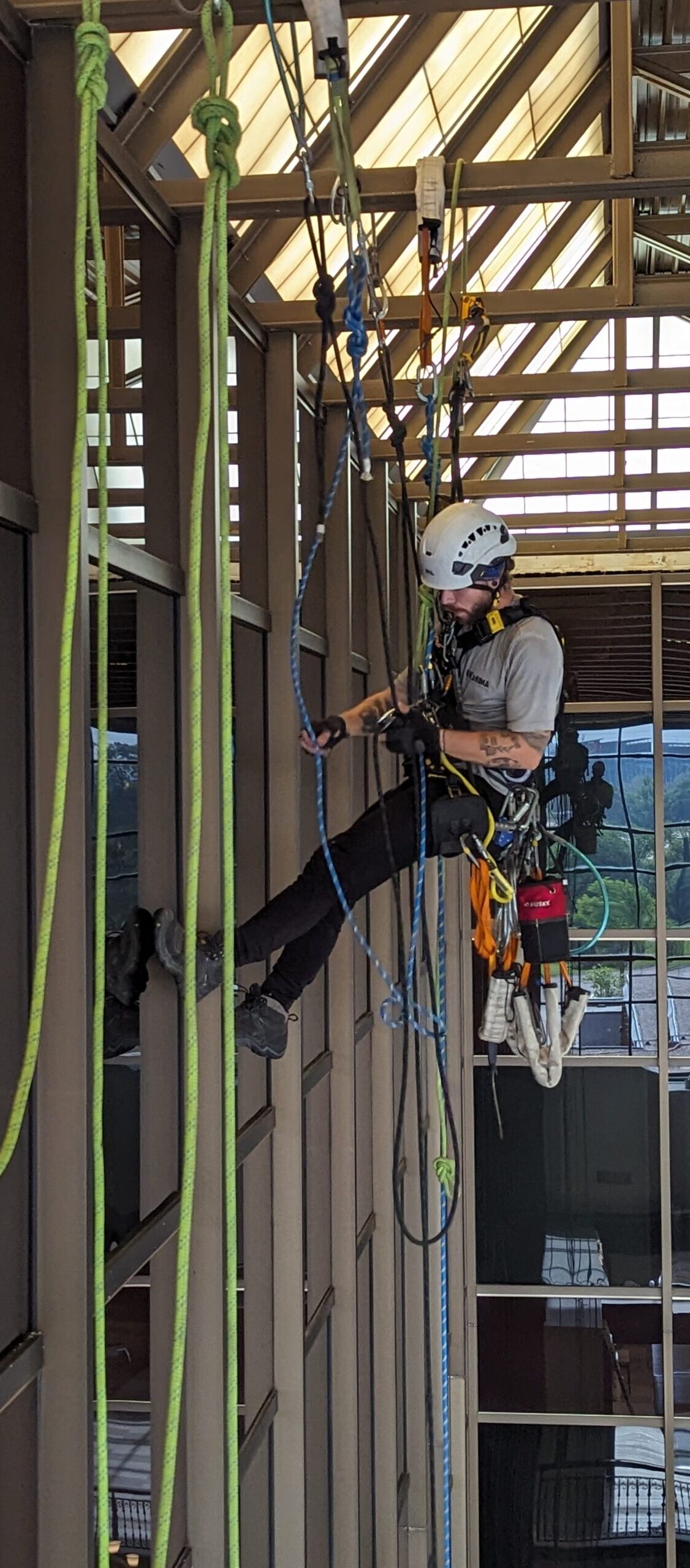

We are committed to finding the safest and most efficient solutions to accessing hard to reach areas by using rope access systems. Through applying our knowledge of rope systems, we aim to offer an experience absent of the use of; cranes, suspended platforms(swing stages), boom lifts, electric lifts, scaffolding and other means of working at height. Moreover, using ropes systems and applying rope access practices we can eliminate; noisy diesel engines, cost of road permits and road closure, cost of heavy machinery rentals, potential for property damage, large work zones, extensive equipment setup, unnecessary emissions.

What sets us apart is that we practice rope access safety standards and rigging in accordance to SPRAT, despite the height or job scope. Every rope system we set considers the potential for a rescue, and is rigged in a fashion to where a rescue can be performed at any moment.

Meet The Team

Zach Hill

Zach Woolfe

Certified Service-Disabled Veteran-Owned Small Business

Maintain the Appearance of Your Building

Rope Access?

- Preparation and Planning: Before accessing the work area, rope access technicians conduct thorough planning and risk assessments. They identify potential hazards, establish rescue plans, and ensure they have the necessary equipment and qualifications for the task.

- Anchor Installation: The first step is to install anchor points securely. These anchor points serve as attachment points for ropes and other equipment. Anchor installation methods vary depending on the surface and structure of the building or terrain. Common anchor types include bolts, straps, and specialized clamps.

- Rigging: Once the anchor points are in place, technicians rig their ropes and other equipment for safe descent and ascent. This involves attaching ropes to the anchors using appropriate rigging techniques, such as friction knots, rigging plates, and pulleys. Rigging systems are designed to provide redundancy and ensure the safety of technicians at all times.

- Descent and Ascent: Using their rope access skills, technicians descend or ascend to the work area using the rigged ropes. Techniques may include single rope technique (SRT), double rope technique (DRT), or a combination of both. Safety backups, such as backup ropes and fall arrest devices, are often employed to mitigate the risk of falls.

- Work Execution: Once in position, technicians perform the necessary tasks, which may include maintenance, inspection, cleaning, painting, installation, or repair work. They utilize specialized tools and equipment designed for use at height, ensuring productivity and safety while working in challenging environments.

- Constant Monitoring and Communication: Throughout the operation, technicians continuously monitor their equipment, surroundings, and personal safety. Effective communication between team members is essential for coordination and response to any unforeseen circumstances or emergencies.

- Retrieval and Exit: After completing the work, technicians carefully ascend back to the anchor points using their rope access skills. They dismantle the rigging system, retrieve their equipment, and exit the work area safely.

- Post-Work Inspection and Documentation: Once back on the ground, technicians may conduct post-work inspections to ensure that the task has been completed satisfactorily and that all equipment is accounted for. Documentation of the work performed, including any observations or recommendations, may also be required for compliance and record-keeping purposes.